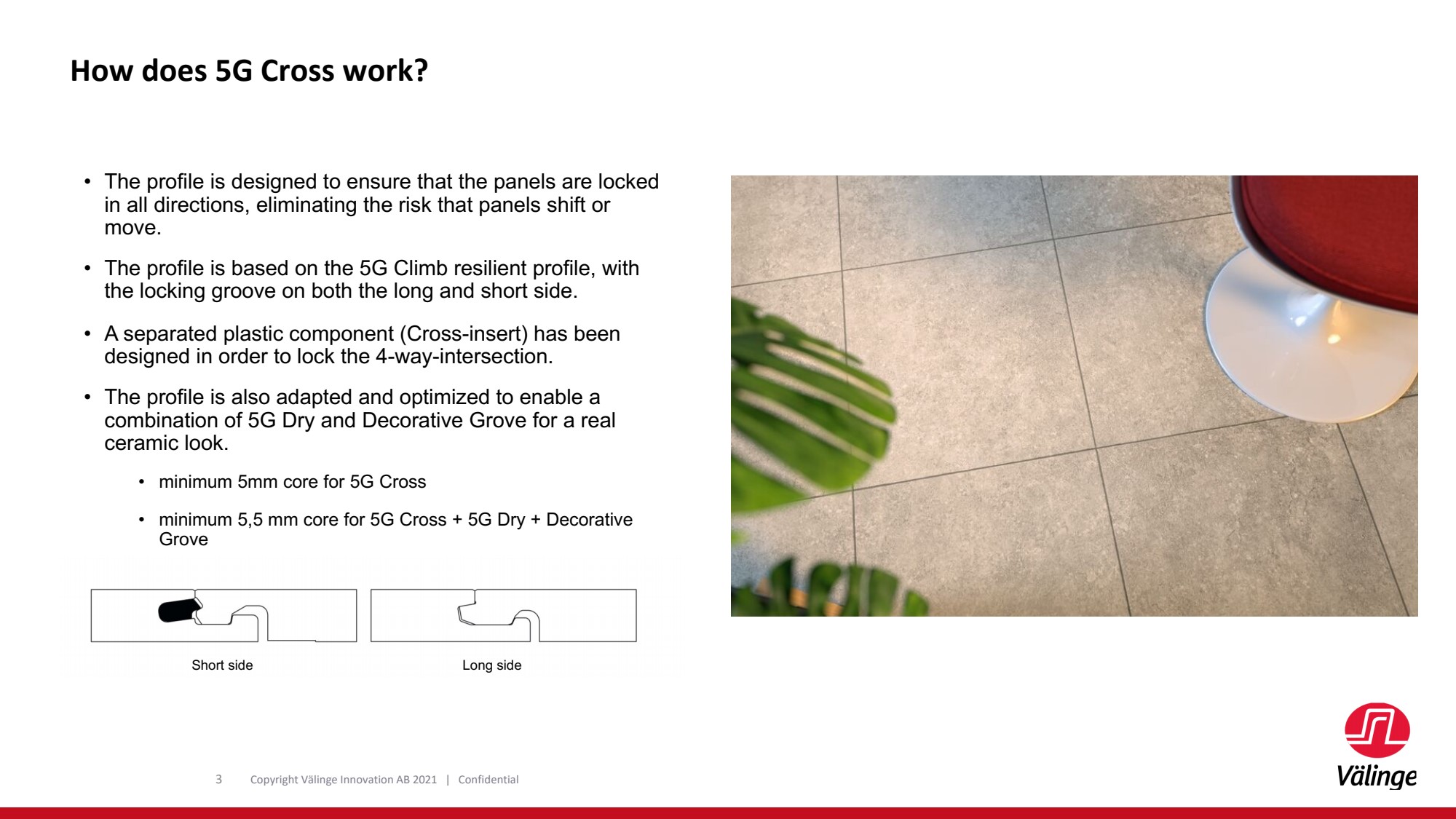

Solid Core Luxury Vinyl Flooring with a 5G® locking profile

General information

This product is a floating floor with excellent acoustic, thermal and waterproof properties made lightweight and rigid to assist installation over uneven subfloor surfaces.

This product will not absorb or be damaged by water. It is essential that these installation instructions are followed to ensure a quality fit. When installed properly and under normal use, damp mopping and topical spills cleaned up promptly will not harm the performance of the floor.

This product is suitable for commercial and residential use, but it is not suitable for installation outdoors nor in rooms that will be continually wet. It is suitable for use in traditional residential bathrooms, kitchens, laundry/ utility rooms.

Install permanent fixtures prior to installation of this product, leaving a space for expansion and contraction, see below.

Fill expansion spaces around potentially wet areas with a flexible acrylic or flexible silicone sealant (neutral cure).

A separate underlay is not normally recommended, refer to supplier.

Acclimation of material

For commercial installations make sure flooring materials are removed from packaging at least 48 hours prior to installation, (planks may be stacked, but must be rested flat) and allowed to condition in the room where the installation is to take place. Room temperature must be kept between 64-81°F (18-27°C).

For residential installations acclimatisation is not essential if the product temperature is already in the range 64-81°F (18-27°C). To achieve a more natural look the product should be shuffled prior to installation.

Subfloors

Before this product may be installed, all subfloors should be solid and sound, smooth and level, clean and swept free of all debris. Measured moisture must be less than 95% RH, (or no more than 5 lbs. moisture/1000 ft per 24 hours: calcium chloride test). Any unevenness in the subfloor should be limited to a maximum of 3/16”(5 mm) below the level in any 10 ft. (3 m) in any direction.

Any isolated highpoints/ridges should first be removed in order to avoid damage to the product.

• Concrete/Screeds: Where the subfloor is uneven an appropriate smoothing compound should be selected.

• Quarry Tiles/Mosaics/Terrazzo/Ceramics: Make sure these floors are solid. Fix any loose tiles. Level any grout lines with a width and/or depth of more than 3/16” (5 mm).

• Wood floors: These should be solid with little flexibility. All loose boards must be firmly fastened, and gaps filled. Wood block floors laid direct to earth/bitumen/ pitch must be removed prior to installation.

• Linoleum/Thermoplastic/Vinyl/Cork Floors: Make sure these floors are solid; fix any loose tiles.

• Miscellaneous: Any existing floors installed with asphaltic tile adhesive (Cutback) must first be suitably covered/ encapsulated or mechanically removed or abated.

• Metal and painted floors: Remove any loose paint or other finishes.

• Textile floor coverings (including carpet) must be removed.

• Underfloor heating: it is possible to install this product over floors incorporating underfloor heating, but these must be controlled to keep the temperature at the interface between the backing and subfloor surface at no more than 81°F (27°C).

• Electrical underfloor heating: please consult manufacturers to ensure their system is compatible with our flooring. Mesh/wire systems must be embedded into a basecoat of reinforced smoothing compound to a minimum depth of 3/8” (10 mm), installed to manufacturers instructions. This product must always be installed over a solid base.

• The room temperature must be between 64-81°F (18-27°C) prior and during installation.

• Other floors: Consult your supplier.

Installation

This product should be installed with an expansion gap of 3/16” (5 mm) around the perimeter of the room and all fixed objects, including pipes. This must be increased to 5/16” (8 mm) for areas larger than 1000 sqft. (100 m²).Consult your supplier for larger areas.*

Base boards should be removed or undercut, and door frames undercut to allow for possible expansion.

Alternatively, a suitable edge trim should be used to cover the expansion gap.

Plank products should be installed with staggered joints, at a distance of at least 10” (250 mm).

Tools

For a successful installation, the following tools will be necessary – pencil, utility knife, ruler/straight edge, carpenter’s square, saw, hand roller, pull bar, hammer, rubber mallet, spade bit and drill (for cutting around pipework) are recommended.

Exclusions

Special care must be taken when installing this product in rooms that are exposed to large temperature fluctuations e.g. unheated rooms, sunrooms or direct sun/through south facing glass doors. In these cases, a 3/8” (10 mm) expansion gap should be used.

Adhesives are not recommended in the installation of this product.

* Where the flooring run exceeds 50ft (15 m) in width or length, an 5/16” (8 mm) expansion joint should be used and repeated thereafter.

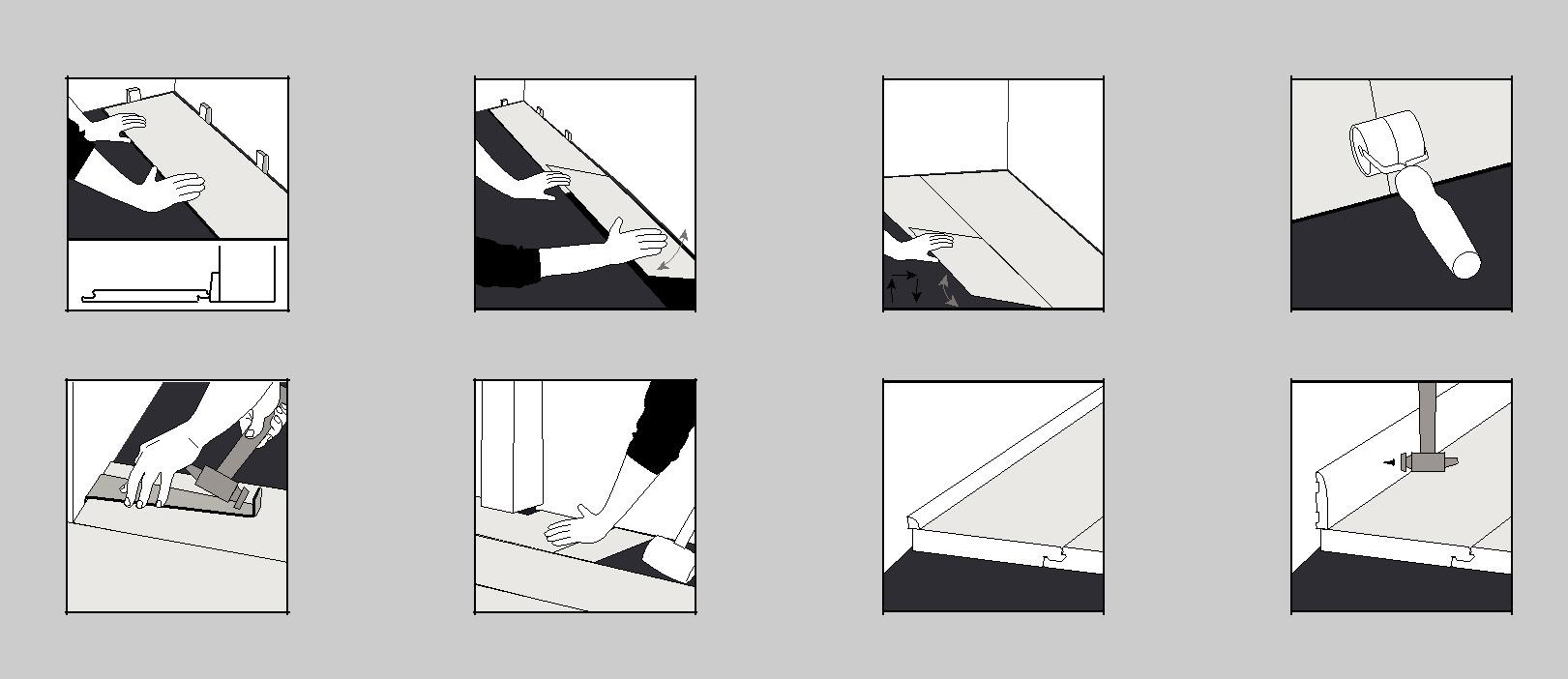

1. Start with a full plank off the wall and measure how many full planks widths there are. If this means there will be a row of narrow planks along the opposite wall, cut the first row of planks accordingly. Install the plank with the tongue side/cut edge facing the wall, fit 3/16” (5 mm) spacers between the plank and wall (Fig. 1).

2. Lay the first row, ensuring the short edges are clicked together (Fig. 2).

3. Using a knife and straight edge, cut the last piece of the row to size making sure that there is a 3/16” (5 mm) gap between the end of the row and the wall.

4. Start the second row by clicking the tongue into the groove holding the plank at an angle (approximately 30°), then tap the plank firmly into the groove of the first row. Install the next plank by easing the tongue and groove together on the long side. The end joint can then be tapped into position with the next plank (Fig. 3).

5. Continue to install planks across the room until the row is complete. Only if really necessary use a rubber mallet and off-cut of product or a hand roller to securely fix the planks together (Fig. 4). A pull bar can be used to pull the product together around the edges of the room (Fig. 5).

6. Repeat section 4 and 5 until the installation is complete.

7. Under door frames: If plank cannot be lifted use an adapted tapping block (or cut off material) and mallet to carefully tap the plank together flat on the floor (Fig. 6).

8. When installing convex corners, around corners or complex profiles, mark the shape on the plank and cut using a saw.

9. Once the floor is installed, remove the spacers; sweep the floor with a soft brush. Fix the base planks or suitable edge trim (available from your local distributor) to cover the expansion gaps. These should be fixed to the wall and not the floor such that the product remains free to expand (Fig. 7 & 8).

Taking care of your floor

• Regularly sweep the floor to remove loose dirt or grit as these can cause fine scratches.

• For a thorough clean, use a pH neutral cleaner. Avoid the use of regular household cleaners and bleach based detergents. These could make the floor slippery or cause discolouration.

• Always mop up spills as soon as possible, to reduce the risk of slipping and possible staining.

• Use entrance mats to protect against grit and moisture. Ensure they are of non-staining variety (not rubber-backed) to prevent any discoloration of the floor.

• Avoid sliding or dragging furniture or other objects across the floor - use floor protector pads to prevent scratching.

• Use large castor cups or other means to protect against indentation from heavy furniture.

• Maintain room temperature between 64-81°F (18-27°C) for optimum performance.

• Do not subject this product to standing water as this will present a slip hazard.

For product questions please contact the flooring dealer where you made your purchase.